ECONOMICAL VERSION WITH HALF ENCLOSURE: TOP + FACE SHARPENING MACHINE WITH DOUBLE-WHEEL FOR CARBIDE CIRCULAR SAWS: ALL THE GEOMETRIES UP TO Ø850MM.

HIGHLIGHTS

- All the features of the AVB 850 model in a more economical half-enclosure format

- The fastest grinder in our range: fully sharpen your blade in a single setup

- EASY TO USE: 10" color touchscreen with guided instructions

- LOW MAINTENANCE: no hydraulics for hassle-free servicing

- 5-axis CNC for automatic operation

- Compact machine with wide blade diameter range: from Ø100 to 850 mm

ELITE AVB 750. MACHINE BASE.

The ELITE AVB 750 is our sharpening machines for face and top of all standard tooth geometries in carbide-tipped circular saw blades, from Ø100 to 850 mm. It includes all features of the AVB 850, but with a half-enclosure design that makes it more affordable and easier to handle.

Total sharpening time (face + back): 12 minutes 33 seconds

Face + top grinding in a single setup: ELITE AVB 850 model

Sahrpening of the top of the teeth in one-pass for tooth types:

- Flat, inclined, alternating, alternating with bevel, pointed, trapezoid, trapezoid-flat, pointed-flat, alternating-flat, trapezoid-trapezoid.

With 5 CNC axis for complete machining of all common tooth geometries in one cycle, particularly short strokes ensure fast sharpening operation.

Its half-enclosure design offers quick access for saw blade placement and maintenance.

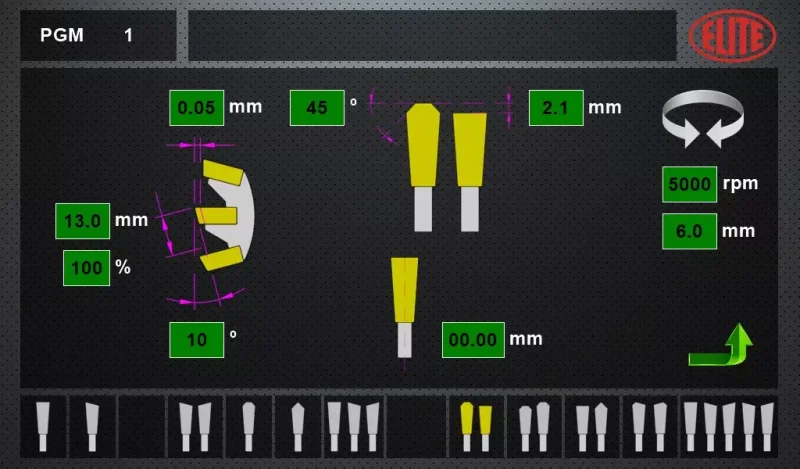

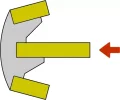

TOOTH TOP: PROGRAM CONFIGURATION

The touchscreen for quick and easy programming.

The tooth shape can be selected at the bottom of the screen. The data required for tooth sharpening appears in the center of the screen when the tooth type is selected.

You can choose the sharpening order: first sharpen the top of the tooth, then the face; or in reverse order: first the face and then the back.

The machine will automatically sharpen the entire saw teeth (top + face) to obtain a completely finished saw.

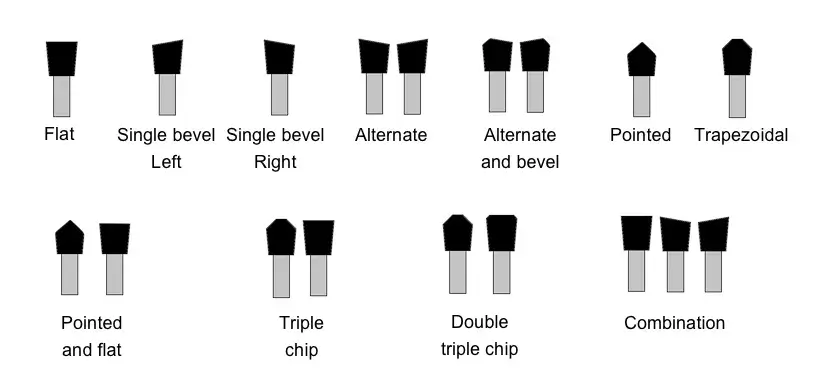

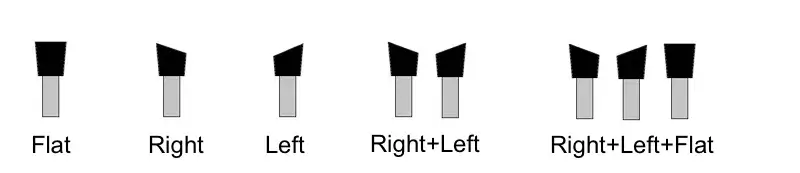

STANDARD TOOTH TOP SHAPES

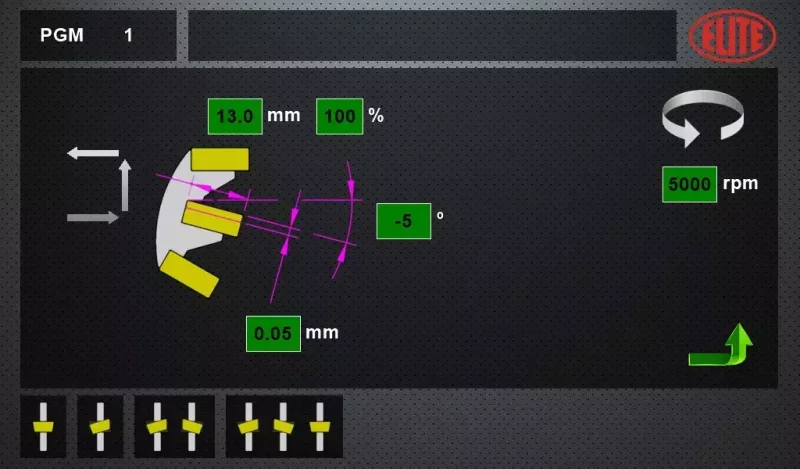

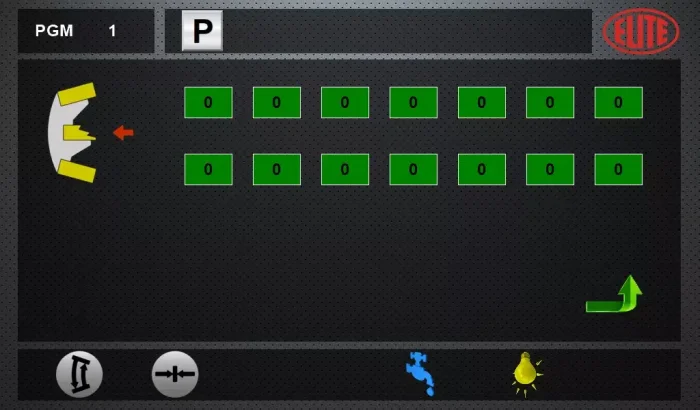

TOOTH FACE: CREATING THE SHARPENING PROGRAM

The face sharpening programming screen allows you to select, among other things, the type of grinding wheel sharpening operation: Start sharpening the tooth, move the wheel away, and exit without sharpening. Or start sharpening and exit polishing the tooth with the wheel.

You can also select the direction of rotation of the grinding wheel: left, right, or change direction for each tooth. You can also select the rotation speed of the grinding wheel.

The tooth shapes allowed are varied: flat tooth, side angle, angle on both sides, or a combination.

Grinding the shear angle

STANDARD TOOTH FACE SHAPES

BROKEN TEETH OR NEW TEETH

You can easily add and edit broken teeth or new teeth. This feature can then be activated or deactivated without having to change the entered values. Very useful, for example, for skipping broken teeth when sharpening the face, but deactivating this option when sharpening the back.

VARIABLE PITCH: Precision and flexibility for complex geometries

The Tooth Pitch mode on the ELITE AVB 750 allows for highly precise programming and adjustment of the distance between teeth, accommodating a wide range of pitches including variable pitch and special tooth configurations. This system ensures perfect synchronization between the saw blade’s feed motion and the grinding cycle, delivering consistent sharpening quality regardless of tooth design.

With its intuitive interface, the operator can manually enter the desired pitch or select from pre-set parameters. The machine automatically detects each tooth position and adjusts the feed smoothly and accurately, reducing setup times and eliminating indexing errors.

This mode is especially valuable for saws with complex geometries or mixed production runs that require frequent pitch changes. Its precision improves tool life and significantly reduces grinding wheel wear.

ELITE AVB 750. HOW IT WORKS

Automatic operation using 5 CNC axis:

A: Tooth pitch

B: Tooth cutting angle

C: Bevel angle of the tooth

X: Sharpening infeed

Z: Sharpening path

Easy to use control panel

The color touch screen control panel allows creation or editing of a program while the machine is working on another program. Among the programmable values are:

• Tooth angle programming. The wheel axis is automatically positioned to the value entered in the program

• Tooth geometry

• Sharpening path

• Sharpening infeed

• Sharpening speed

• Tooth pitch

• Indexing finger feed rate

• Number of teeth

• Broken teeth

Up to 10 teeth/minute when grinding circular saw blades with flat-triple chip teeth

Up to 10 teeth/minute for the most typical tooth geometry: flat-triple chip. All movements have been optimized to reduce downtime. Making the AVB 750 a very fast grinding machine, allowing a 96-tooth flat-triple chip circular saw blade to be grind in less than 10 minutes.

Variable wheel rotation speed from 2,500 to 5,000 RPM

Variable wheel rotation speed from 2,500 to 5,000 RPM. Includes a variable frequency drive as a standard feature, allowing you to adjust the grinding wheel speed to the optimal value required and reduce energy consumption.

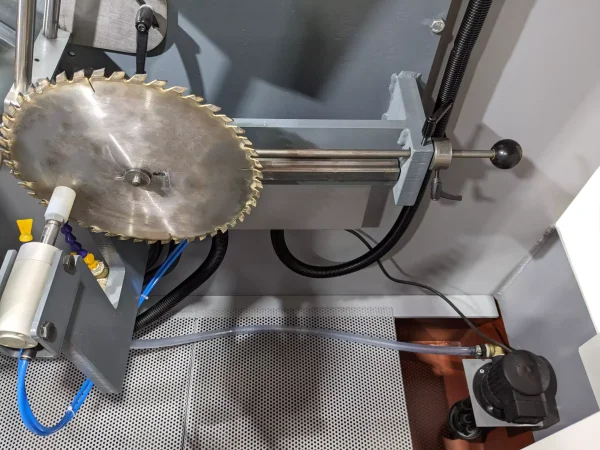

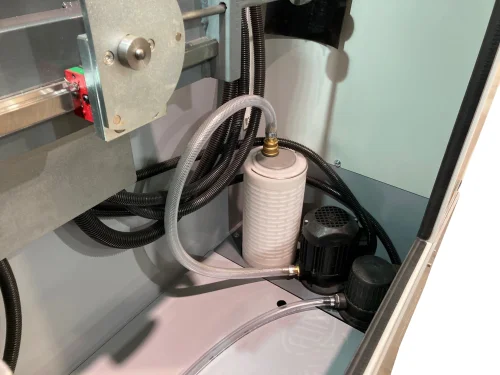

Integrated cooling system

Machine operates with water-soluble coolant for better sharpening quality and longer grinding wheel life time.

Integrated coolant system with 220-liter tank and removable grates for easy cleaning.

Easy access and maintenance

At the back of the machine we find the electrical panel at the bottom and the mechanical system at the top, both protected by their corresponding easy-access panel, which also reduces the total space needed for the machine.

ELITE AVB 750. EQUIPMENT INCLUDED

- Grinding wheel holder for face and top grinding wheels

- ø2 or ø3 mm. indexing finger

- Device for sharpening saws of equal diameters

- Prepared for connection to a filtration system or a centralized filtration system.

ELITE AVB 750. SPECIFICATIONS

| TECHNICAL DATA | AVB 750 |

|---|---|

| Saw blade outside diameters | From ø100 to ø850 mm. |

| Saw blade hole diameter | From ø10 mm. |

| Saw body thickness | Up to 8mm. |

| Tooth pitch | Up to 125 mm. CNC control |

| TOP GRINDING | |

| Clearance angle | From +5º to +35º |

| Bevel angle | From -45º to +45º |

| Grinding path | Up to 25mm. |

| Available tooth shapes | Flat (F) - Single Bevel (L/H or R/H) - Alternate (ATB) - Alternate and bevel (HGB) - Pointed Tooth (PTR) - Trapezoid (D/T/C) - Combination (SLR) |

| FACE GRINDING | |

| Hook angle | From -10º to +35º |

| Grinding path | Up to 25mm. |

| Available tooth shapes | Flat (F)- Single Bevel (L or R) - Alternate |

| OTHER INFORMATION | |

| Grinding wheel motor | 2 HP |

| Total connected power | 2.5 kW |

| Grinding wheel speed | Adjustable from 2500 to 5000 RPM |

| Diameter of the grinding wheel for top | ø125 mm. |

| Diameter of the grinding wheel for face | ø175 |

| 4 axis CNC | A: Feed pawl - C: Lateral angle of the top of the tooth - X: Grinding load - Z: Grinding path |

| Machine dimensions | 1430x 1285 x 1820mm. |

| Machine weight | 620 kg. |

TECHNICAL REQUIREMENTS

6 bar pneumatic air connection required.

Connection voltage: 220 2Ph 50/60Hz

Required connection power: 2.5 kW

RECOMMENDED OPTIONAL ACCESSORIES

- Saw holder for circular saw blades with outer ø200-450, ø400-650, and ø600-850 mm.

- Centering rings for circular saw blade bore holes, of various sizes.

- Reinforced saw holder device

- Filtration system: ELITE FILTRAmaq UNO, SOLO, or PRO models. Filtration down to 2 µm. Recommended for improved sharpening quality.

DOWNLOAD LEAFLET

REQUEST INFORMATION

MACHINES COMPARISONS AT A GLANCE

| MODEL | TOP GRINDING | FACE GRINDING | BACK OFF GRINDING | SIDES GRINDING | SEAT POCKET GRINDING | AUTOMATIC MEASUREMENT |

|---|---|---|---|---|---|---|

| AVB 851 | All tooth shapes | All tooth shapes | No | No | No | Yes |

| AVB 850 | All tooth shapes | All tooth shapes | No | No | No | No |

| AVB 750 | All tooth shapes | All tooth shapes | No | No | No | No |

| AVB 2200 | All tooth shapes | All tooth shapes | No | No | No | No |

| SVG 900 | All tooth shapes | Flat teeth | No | No | No | No |

| SVG 850 | All tooth shapes | Flat teeth | No | No | No | No |

| SVG 750 | All tooth shapes | Flat teeth | No | No | No | No |

| MVB 900 | Flat teeth | Flat teeth | Yes | No | Yes | No |

| MVB 850 | Flat teeth | Flat teeth | Yes | No | No | No |

| MVB 750 | No | No | Yes | No | No | No |

| MVB 670 | Chipbreaker slots | No | No | No | No | No |

| MVB 650 | No | Hollow face | No | No | No | No |

| GBT 851 | No | No | No | Yes both sides at same time | No | Yes |

| GBT 850 | No | No | No | Yes both sides at same time | No | No |

| GBT 750 | No | No | No | Yes: One side at a time | No | No |