MANUAL SIDE GRINDING MACHINE FOR REPAIRING CARBIDE-TIPPED CIRCULAR SAW BLADES UP TO ø33,4".

.webp)

HIGHLIGHTS

- Integrated cooling unit as an option

- Robust and very simple design that allows continued use of the machine without breakdowns

- Easy to use

- Very compact machine with a wide range of disc diameters: from ø3,93" to 33,4".

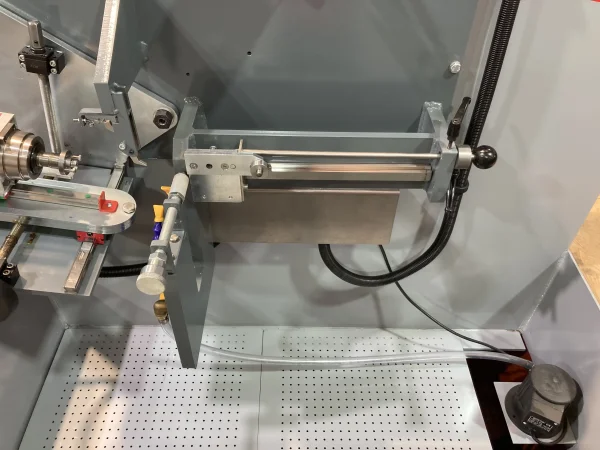

ELITE GBT 750. MACHINE BASIS.

The ELITE model GBT 750 is our side grinding machine for circular saws blades with tungsten carbide teeth that is very easy to work thanks to its manual grinding operation.

It is equipped with a single wheel.

Saw diameter from ø3,93" to grind the sides of scoring discs or portable machines.

It can index any type of tooth pitch.

It allows for precise and rapid grinding of tooth sides to manufacture carbide-tipped circular saw blades or for tip replacements.

ELITE GBT 750. HOW IT WORKS

Simple and easy-to-use control panel that allows you to select left or right grinding wheel direction.

The grinding wheel motor with a motorized direct spindle system rotates at 9000 RPM for optimum sharpening quality with minimal stone wear. It is driven by a frequency converter.

The grinding wheel motor with a motorized direct spindle system rotates at 9000 RPM for optimum sharpening quality with minimal stone wear. It is driven by a frequency converter.

Saw diameter

Saw diameter from 100 mm.

It can grind both sides of the tooth by placing the grindind head first to one side an then to the other one.

Allows the indexing of any type of tooth pitch.

Sharpening the sides of the teeth

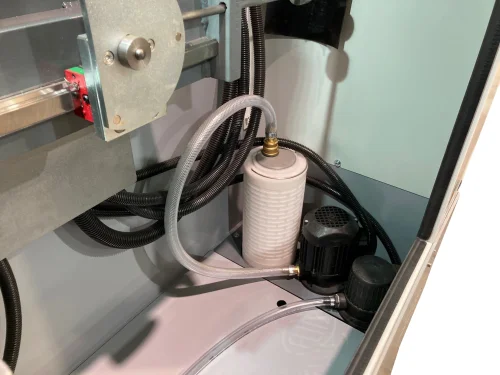

Integrated refrigeration equipment

It allows wet sharpening with water-soluble coolant for better sharpening quality and longer grinding wheel life. for better surface quality and longer grinding wheel life.

Integrated coolant system with 220-liter tank and removable grates for easy cleaning.

Available as an option.

Easy access

Easy access for servicing the manual grinding machine for repairing carbide-tipped circular saw blades ELITE model GBT 750

Clean design and easy access for servicing or repairing the machine.

Easy maintenance

The electrical panel is located at the bottom and the mechanics at the top of the machine, protected by an easy-to-open cover.

The electrical panel is organized in a clean way, so maintenance is simple when necessary.

The electrical panel is organized in a clean way, so maintenance is simple when necessary.

ELITE GBT 750. EQUIPMENT INCLUDED

- Grinding wheel holder for the grinding wheel.

- Device for sharpening saws of equal diameters

- Prepared for connection to a machine filtration system or a centralized filtration system.

ELITE GBT 750. SPECIFICATIONS

| TECHNICAL DATA | GBT 750 |

|---|---|

| Saw blade outside diameter | From ø4" to 33,5" |

| Saw blade hole diameter | From ø0,39" |

| Saw blade thickness | Up to 0,31" |

| Tooth pitch | Any tooth pitch is possible |

| SIDES GRINDING | |

| Grinding path | Up to 1,57" |

| Rake angle | From -15º to +30º |

| Radial cutting angle | Up to +6º |

| Tangential cutting angle | Up to +6º |

| REFRIGERATION EQUIPMENT | Optional |

| Tank capacity | 220 liters |

| Coolant flow rate | Up to 40 liters/minute |

| TECHNICAL DATA | |

| Motor wheel | 0,75 kW |

| Wheel speed | 9000 RPM |

| Grinding wheel diameter | ø3,9" |

| Grinding wheel hole diameter | ø0,78" |

| Machine dimensions | 1570 x 1180 x 1780mm. |

| Machine weight | 470 Kg. |

TECHNICAL REQUIREMENTS

Connection voltage: 220-240V 2Ph 50/60Hz

Required connection power: 1.5 kW

RECOMMENDED OPTIONAL ACCESSORIES

- Saw holder for circular saws external ø7.8"–17.7", ø15,7"–25,5", and ø23,6"–33,4".

- Centering rings for circular saws bore hole of various sizes.

- Filtration system: ELITE FILTRAmaq UNO, SOLO, or PRO models. Filtration down to 2 µm. Recommended for improved sharpening quality.

DOWNLOAD LEAFLET

REQUEST INFORMATION

MACHINES COMPARISONS AT A GLANCE

| MODEL | TOP GRINDING | FACE GRINDING | BACK OFF GRINDING | SIDES GRINDING | SEAT POCKET GRINDING | AUTOMATIC MEASUREMENT |

|---|---|---|---|---|---|---|

| AVB 851 | All tooth shapes | All tooth shapes | No | No | No | Yes |

| AVB 850 | All tooth shapes | All tooth shapes | No | No | No | No |

| AVB 750 | All tooth shapes | All tooth shapes | No | No | No | No |

| AVB 2200 | All tooth shapes | All tooth shapes | No | No | No | No |

| SVG 900 | All tooth shapes | Flat teeth | No | No | No | No |

| SVG 850 | All tooth shapes | Flat teeth | No | No | No | No |

| SVG 750 | All tooth shapes | Flat teeth | No | No | No | No |

| MVB 900 | Flat teeth | Flat teeth | Yes | No | Yes | No |

| MVB 850 | Flat teeth | Flat teeth | Yes | No | No | No |

| MVB 750 | No | No | Yes | No | No | No |

| MVB 670 | Chipbreaker slots | No | No | No | No | No |

| MVB 650 | No | Hollow face | No | No | No | No |

| GBT 851 | No | No | No | Yes both sides at same time | No | Yes |

| GBT 850 | No | No | No | Yes both sides at same time | No | No |

| GBT 750 | No | No | No | Yes: One side at a time | No | No |

.webp)